Welding Materials: How to estimate input and consumption materials for welding pipes. Calculation tables by joint type and welding method.

Welding Materials: How to estimate input and consumption materials for welding pipes. Calculation tables by joint type and welding method.

Contribution and consumption of welding materials

Carbon steel pipe welding is a manufacturing process used to join individual sections or pieces of carbon steel pipe by melting and fusing them together.

The goal is to create a strong, continuous bond between the pipes to ensure the structural integrity and functionality of the overall system.

This welding process is widely used in various industries such as oil and gas, construction, petrochemical and others where the transport of liquids or gases through pipelines is a basic requirement.

In this article, we will analyze how to estimate the input and consumption materials for welding carbon steel pipes.

Difference between the input material and the consumable material

A consumable is any material used to perform a task that is not incorporated into the structure.

On the other hand, input materials are the raw materials or components used in the manufacturing process to create a finished product. These materials are usually transformed or processed during the manufacturing process and become part of the final product. (Example: electrodes, welding wire).

Estimating the quantity and cost of input and consumable materials varies from project to project and must be analyzed on a case-by-case basis.

We need to gather and document the data for the project in question, including the specifications of the pipes and the welding process(es).

The steps to follow can be summarized as follows:

Project information:

- Project Name: [Enter project name]

- Project ID: [Enter Project ID]

- Date: [Enter date]

Piping details:

- Pipe class/service

- Pipe size/specification

- Design code

Welding process to be used as indicated by the Welding Technical Specifications applicable to the Project.

Welding technical specifications.

Welding technical specifications are detailed documents that outline the specific requirements, procedures, and quality standards for welding processes.

Contribution and consumption of materials in welding processes.

The following must be identified in order to calculate the input and consumption of materials in welding processes:

- 1. The wire or electrode to be used: this is taken from the welding technical specifications.

- 2. Estimating the quantity and type of wire or electrodes to be used can be solved using the Welding Material Calculation Tables 1 and 2

- 3. Identification and quantity of the type of shielding gas to be used (e.g. argon, CO2) for welding carbon steel pipes. Tables 1 and 2 are also used for this estimation.

Welding Materials – Calculation Tables: Table 1

In this case, the table shows the weight of metal deposited in different types of joints per linear meter.

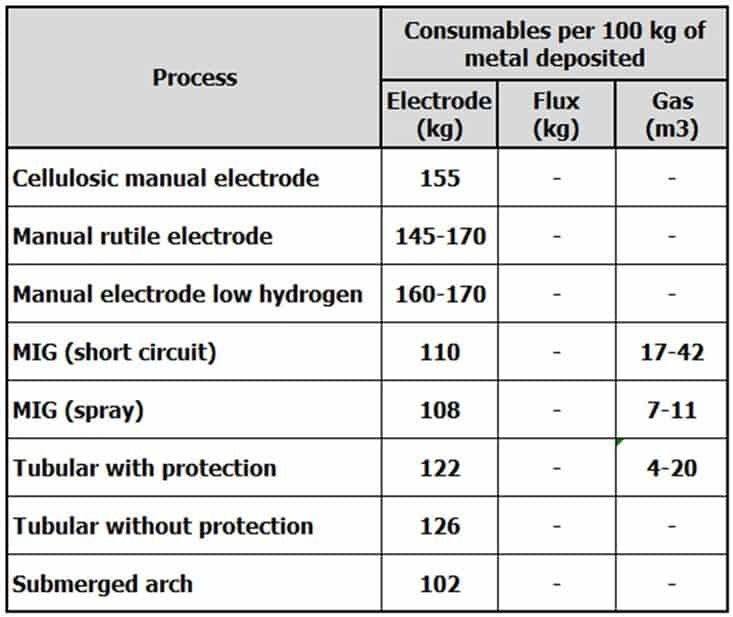

Welding Materials – Calculation Tables: Table 2

This table allows us to calculate the input and consumption for each welding process when depositing 100 kg of metal.

Attention:

If our project requires a significant number of pipe welds, input costs and material consumption can be significant.

The above is especially important in cases where alloy or special steels are being welded.