Piping material take off. In the context of piping installation, Materials Take Off is the process of quantifying and determining the types and quantities of materials required for a particular project or piping installation.

Piping material take off. In the context of piping installation, Materials Take Off is the process of quantifying and determining the types and quantities of materials required for a particular project or piping installation.

To prepare the MTO for any project, only the plans, technical specifications, and all other relevant documents that have been deemed suitable for construction should be utilized.

Performing the MTO accurately helps project managers, and procurement teams to accurately calculate the materials, costs and timings required for the successful installation of the piping system.

General steps to perform an MTO for a piping system include:

Identify Components

Identify the various components of the piping system, such as pipes, fittings, valves, flanges, supports, gaskets, bolts, and nuts, and all other required accessories. Be aware of their dimensions, types of materials and specific requirements.

Measure Lengths

Measure the lengths of each type of pipe required based on the drawings and specifications. Take into consideration the pipe routing, elevations, and any allowances for piping works. Compute the total linear length for each type of pipe.

Count Fittings and Accessories

Count the number of fittings needed for the piping system, such as elbows, tees, reducers, and couplings. Include accessories like gaskets, bolts, nuts, and washers as well.

Valve Quantities

Identify and count the number of valves needed, including gate valves, ball valves, check valves, control valves, instruments and all other types of elements specified in the drawings.

Supports

Determine the quantities of supports, such as hangers, brackets, and insulation materials, based on the project requirements.

Determine Quantities

Using the information gathered, calculate the quantities of each material required by adding the lengths of pipes, number of fittings, valves and accessories. Consider the tolerances for waste, additional lengths for connections, or additional materials for contingencies.

Consider Special Requirements

Consider Special Requirements: Take note of any specific requirements mentioned in the specifications or project documents, such as insulation, coatings, protective measures, or special supports.

Create a Materials Take Off

Generate a detailed list of all the materials and quantities needed for piping assembly. This document is an essential guide for procuring and ordering materials.

Verify and Double-check

Accurate take-off in piping assembly is critical to estimating project costs, determining material requirements, and ensuring smooth execution of the construction process. This checklist assists with planning, budgeting and management.

Summary

Taking off for piping assembly requires particular attention to detail and a good understanding of construction drawings and specifications. It assists project managers, and procurement teams to accurately estimate material requirements, costs and planning for the successful installation of the piping system.

Using specialized software to perform a piping takeoff can greatly streamline the process and improve accuracy.

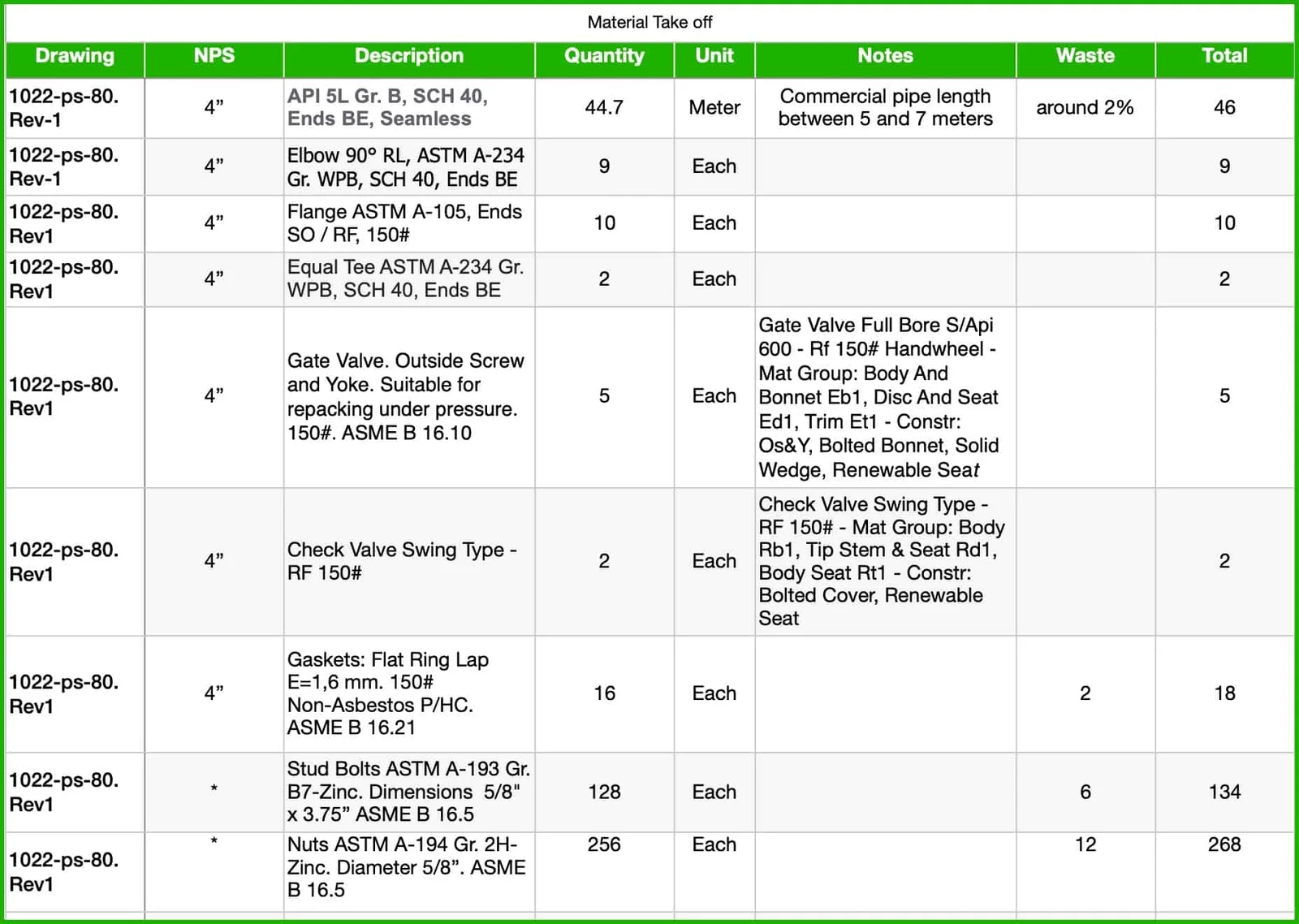

Piping material take off – Checklist: Sheet Example

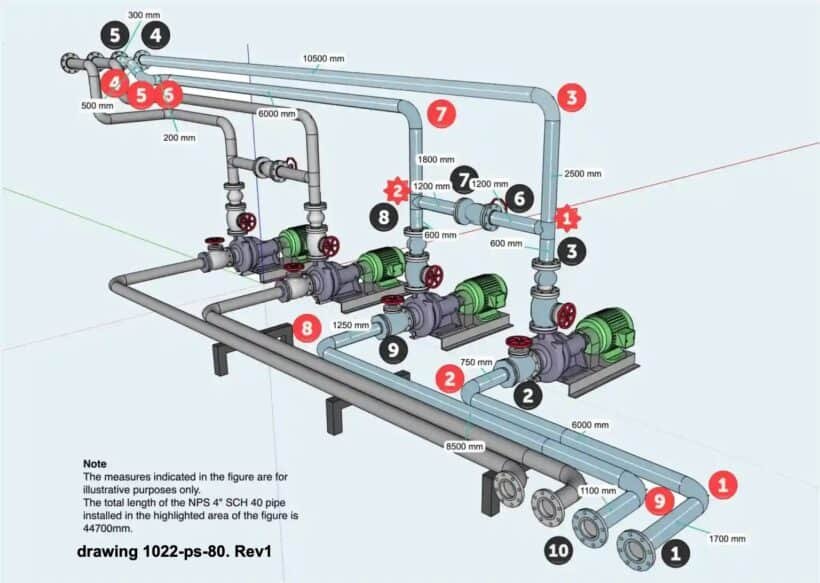

MTO Checklist Sheet Example. This example, provides a precise list of the materials and quantities needed to construct the piping system highlighted in the light blue color of the drawing 1022-ps-80. Rev1, qualified as suitable for construction.

In the next post will address topics such as coatings, supports, and input and consumption materials.

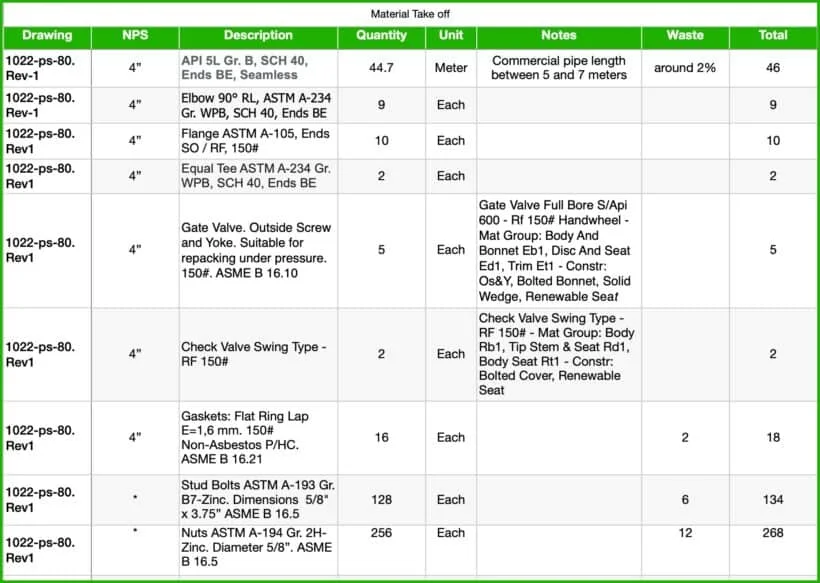

Piping MTO Sheet

Piping MTO Sheet. The worksheet identifies the different components of the piping system, such as pipes, fittings, valves, flanges, gaskets, bolts, and nuts.

The different columns display the quantity of materials, size, types of materials, and special requirements.

In the next post, we will discuss piping MTO for the welding materials.

MTO Checklist – Calculate Man Hours