Check valve or a non return valve

The check valves permit flow only in one direction. These valves close when the flow rate is inverted. Also known as non return valve (NRV)

The check valves permit flow only in one direction. These valves close when the flow rate is inverted. Also known as non return valve (NRV)

The non-return valve (NRV) or foot valve works on the principle of differential pressure. In simple terms, the valve will open only when the downstream pressure is lower than the upstream pressure. If the downstream pressure exceeds the upstream pressure, the valve will close to prevent the return of liquid.

The valve closure mechanism varies depending on the size and design of the valve. Gravitational or spring pressure is used to close the valve.

The check valves have an arrow on their body which represents the direction of the fluid flow.

Types of NRV valve

The type of disc determines the type of valve. The most common kinds of non-return valves are:

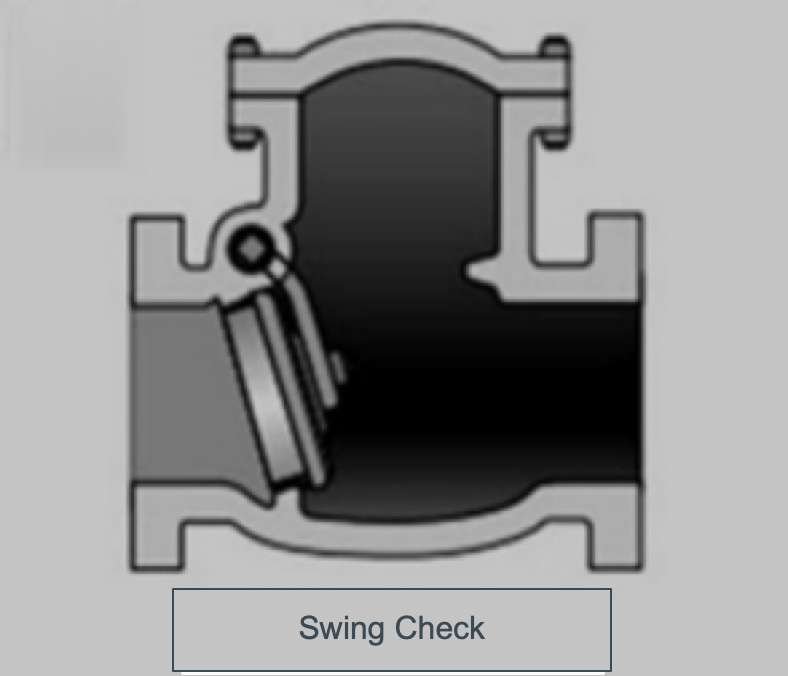

Swing Type – Top Hinged

In the swing valve, a swing flap acts as a shutter and closes the flow by gravity, when the fluid flows in an undesirable direction.

Because they work by gravity, we have to place them in the right position.

The angle between the seat and the vertical plane is called the seat angle and ranges from 0 to 45 degrees. Typically, seat angles are 5 to 7 degrees. Larger seat angles reduce the disc travel, resulting in quick closing, thus minimizing the possibility of a water hammer. A vertical seat has a 0-degree angle.

The swing-type valve allows full, unobstructed flow and automatically closes as pressure decreases. Usually installed in combination with gate valves.

A basic swing type valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. This is illustrated in the following picture.

These valves are usually used in sizes of two inches and greater. Swing check valves can be mounted horizontally and vertically. They are not suitable for pulsating flow.

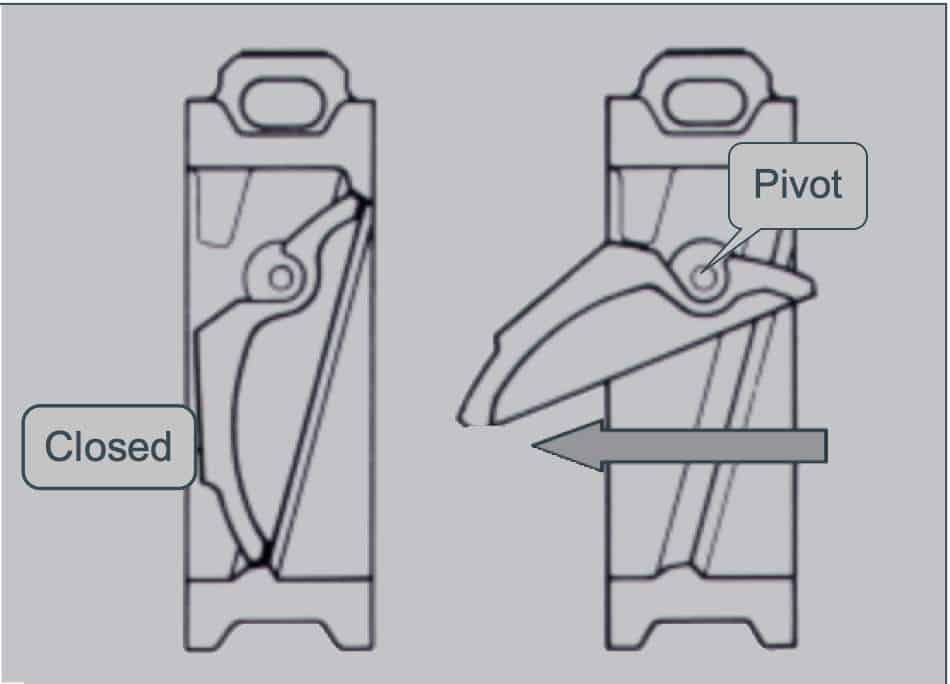

Tilting disk – Check valves

A tilting disc check valve is a check valve wherein the disc has a pivot point in the middle of the disc. It is also known as a tilt check valve or a tilting-disk check valve. When flow is moving forward, the valve easily opens and when there is flow reversal, the valve immediately closes

Tilting disc check valves are generally used in agricultural applications but they may be used in other applications as well. Valves are used in case of frequent inversion of flow.

Lift Type (piston and ball)

The seat design of a lift-Check valve is similar to a Globe valve. The disc is usually in the form of a piston or a ball.

A guide keeps motion of the disc on a vertical line, so the valve can later reset properly

Lift Check valves are particularly suitable for high-pressure service where the velocity of flow is high. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. Lift Check valves are suitable for installation in horizontal or vertical pipelines with upward flow.

The flow to lift Check valves must always enter below the seat. As the flow enters, the piston or ball is raised within guides from the seat by the pressure of the upward flow. When the flow stops or reverses, the piston or ball is forced onto the seat of the valve by both the backflow and gravity.

Lift Check valves are particularly suitable for high-pressure service where the velocity of flow is high.

These valves provide superior leak-tight characteristics to those of swing check valves.

All of that is shown in the figure below.

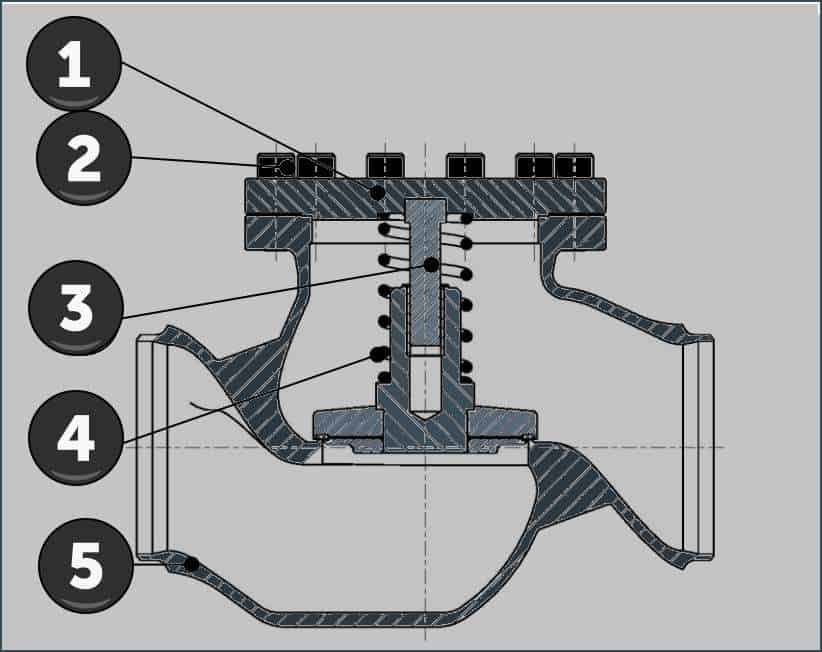

Piston Check Valve

Some design in plug type uses spring to retain the disk in a closed position. This ensures the valve allows flow of fluid only when there is sufficient pressure in the flow direction.

The pressure required from the upstream side of the valve to overcome the spring tension is called ‘cracking pressure’. When the pressure going through the valve drops below the cracking pressure, the spring closes the valve to prevent back flow in the process.

This valve is shown in the figure below.

1-Cap

2-Bolt

3-Obturator

4-Spring

5-Body

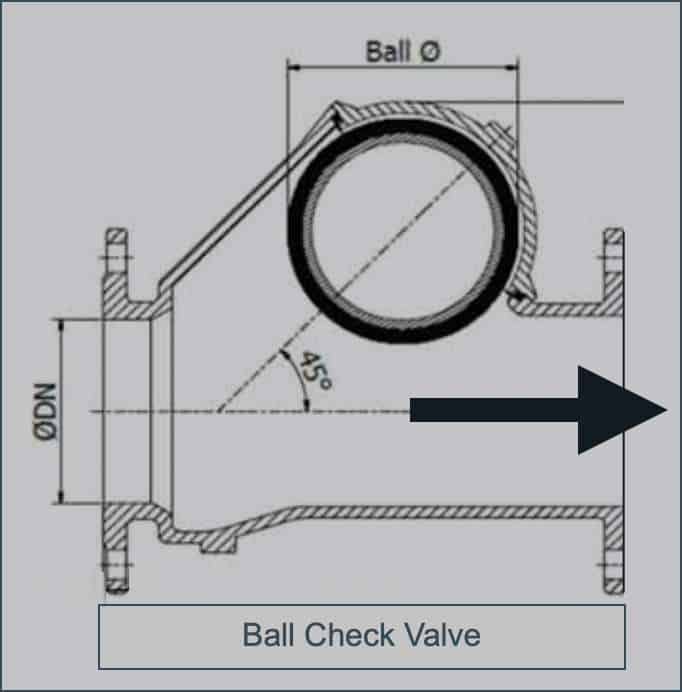

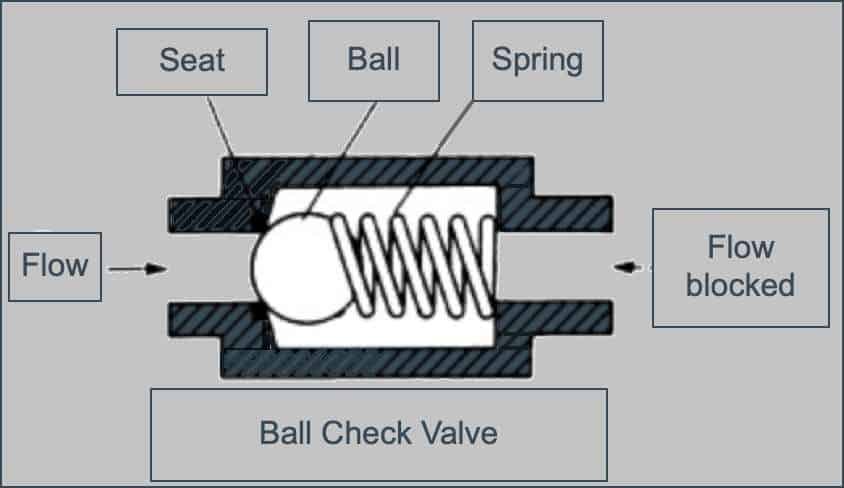

Ball Check Valve

A ball check valve functions by means of a ball that moves up and down inside the valve.

In next the figure we see a different arrangement that shows the ball, the spring and the seat of a valve. This design is used extensively in pneumatic systems.

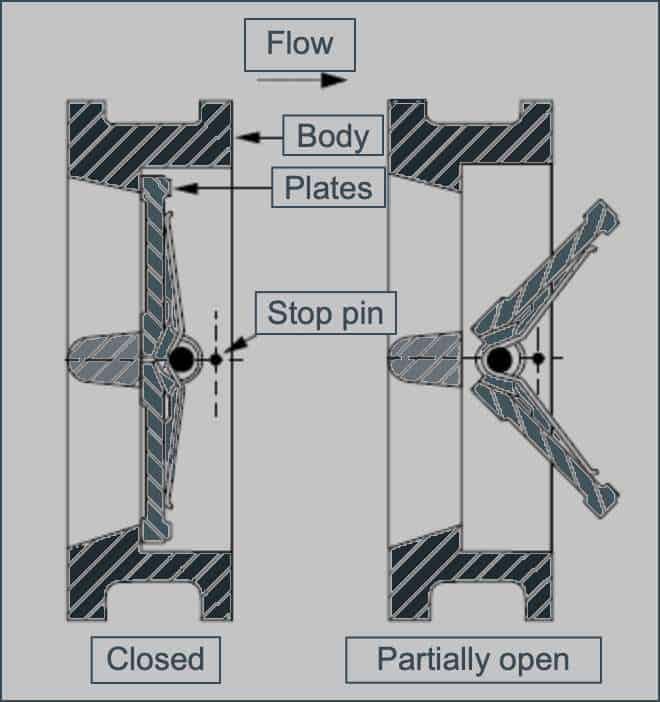

Dual Plate Type (butterfly check valves)

A dual plate check valve is known as a butterfly check valve, or splits disc check valve. In this valve, two halves of the disk, move towards the center line with the stream forward, and with the reverse flow, the two halves open and press the seat to set-off the flow.

Use of dual plate check valve is common in low-pressure liquid and gaseous services. Its lightweight and compact construction makes it a better choice when space and convenience matter.

This valve is 80-90% lighter than a classic check valve. Often used in systems which use butterfly valves. The cost for installation and maintenance is very small compared to other types.

The following diagram shows the valve in the closed position and in the open position.

Stop Check Valves

Stop Check Valve is a combination of a lift check valve and a globe valve. It can either be used as a check valve or as an isolation (stop) valve like a globe valve. These valves can be closed with the help of a stem that is not connected to the valve disc during normal operation and allow use of these valves as a regular NVR.

However, if required, the stem is used to hold the floating disk against the valve seat, just like a globe valve. These valves are available in tee, wye, and angle patterns.

Pros of non-return valves.

Prevent backflow. Protect pumps and compressors from damage caused by backflow

Can be operated horizontally and vertically.

Self-actuated

Fast acting.

Prevent water hammer

Low cost to maintain.

Few mobile parts.

Capable of responding to variable flow conditions.

Does not require power to perform.

View the post about Butterfly Valves

Check Valve – Calculate Man Hours