Gate Valve Types. The Gate valves have three main components: the valve body, bonnet and TRIM.

Gate Valve Types. The Gate valves have three main components: the valve body, bonnet and TRIM.

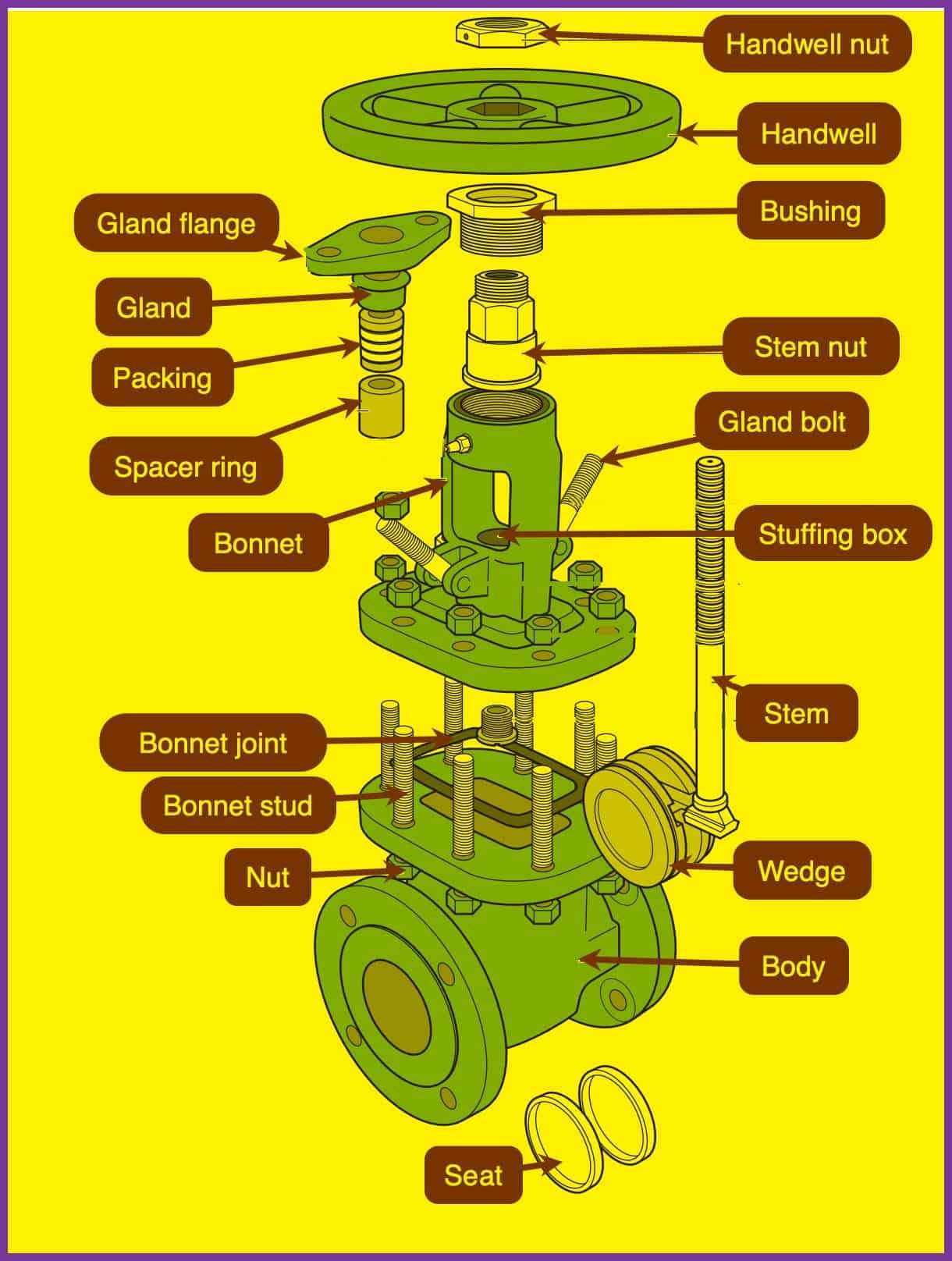

Gate Valve Parts

Body

We usually connect the body to other equipment by flanges or by welding

Bonnet

The bonnet is the upper casing of the valve. It provides a support on which the stem can slide. It acts to seal the valve stem against leaks (usually using a stuffing box and packing).

There are three basic ways of attaching the bonnet to the valve body.

- The threaded bonnet is normally used on small low pressure valves. One issue that can sometimes occur with the screw cover is that the cover can unscrew the valve is actuated. This is caused by a tight or “sticky” stem.

- The bolted bonnet is the type most used at refineries. It is suited to medium/high pressure applications.

- The cylinder head closure is a heavier and more expensive bonnet, normally used for high-pressure work. It uses a seal weld to prevent leakage.

TRIM – Gate Valve Types

TRIM of the valve is the set of internal components.

Depending on the type of valve, the “TRIM” may include stem, disc, seat, etc.

It includes all internal parts in contact with the fluid that is exposed to wear.

“TRIMS” are chosen to be resistant to corrosion, erosion, and wear.

Besides corrosion resistance, pressure, and temperature, the presence of thermal shock, line stresses, and fire hazards are considered for material selection.

The valve body, bonnet, packing, etcetera that also come in contact with the flow medium are not considered “Valve TRIM”.

Fluid properties, chemical composition, pressure, temperature, flow rate, velocity and viscosity are some of the important considerations in the selection of suitable “TRIM” materials.

“TRIM” materials may or may not be identical to the valve body or bonnet.

API has standardized trim materials by assigning a unique number to each “TRIM” material set.

The figure shows the exploded view of a gate valve.

Gate valves require very little clearance along the pipe axis and hardly limit fluid flow when the valve is fully open.

The gate faces can be parallel, but are usually wedge-shaped (in order to be able to apply pressure on the sealing surface).

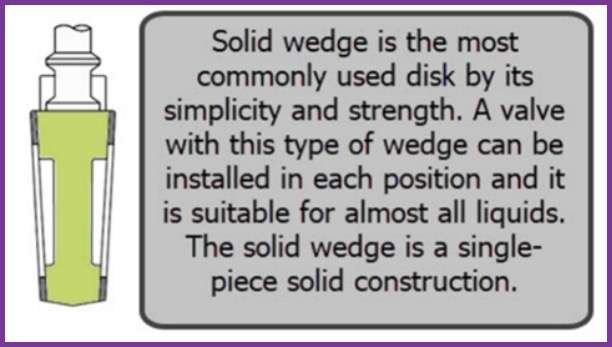

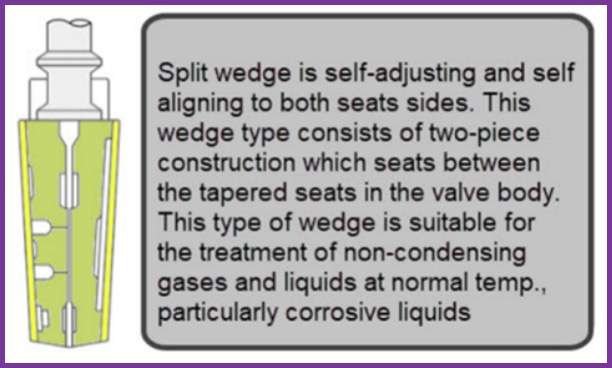

Wedges of a Gate.

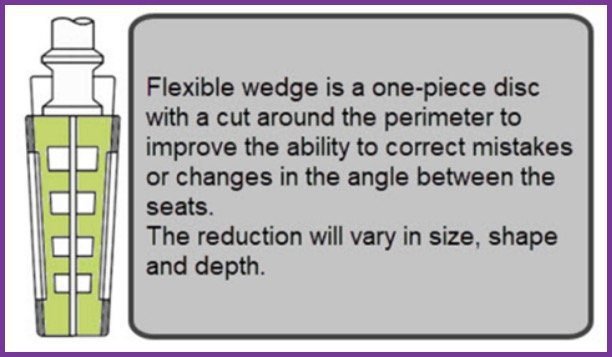

Gate valves are available with different disks or wedges.

The most usual are.

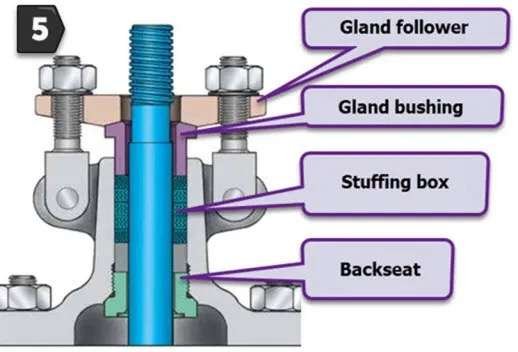

Packing

The packing is a pressure barrier that acts radially by limiting fluid leakage to the outside between the valve stem and where the valve is mounted.

The continuous opening and closing of the valves, as well as the effect of temperature, type of fluid, and packing materials, play an important role in controlling leaks between fixed (stuffing box) and moving (stems) parts.

See figure N°5

The actuator

We choose actuators according to several factors, including the torque required to actuate the valve and the need for automatic actuation.

Actuator types include handwheel, lever, electric motor, pneumatic, solenoid, hydraulic piston, and self-acting.

All actuators, except the handwheel and lever actuators, are adaptable to automatic actuation.

Summary.

The manual actuator is the most common type of valve actuator.

Manual actuators include handwheels connected directly to the valve stem and handwheel connected through gears to provide a mechanical advantage.

Electric motor actuators comprise reversible electric motors connected to the valve stem through a gear train that reduces rotational speed and increases torque.

Pneumatic actuators use air pressure on one or both sides of a diaphragm to provide the force needed to position the valve.

Hydraulic actuators, as their name suggests, use a pressurized liquid on one or both sides of the piston to provide the force needed to position the valve.

Solenoid actuators have a magnetic tab attached to the valve stem.

The force to position the valve comes from the magnetic attraction exerted on the stem by the solenoid coil of the valve actuator.

Note: Gate valves should not be installed with their stem below the horizontal line.

Gate Valve Types – Calculate Man Hours

Publications for further reading