Diaphragm valves include a valve body with two or more ports, a diaphragm, and a weir or seat against which the diaphragm closes the valve.

Diaphragm valves include a valve body with two or more ports, a diaphragm, and a weir or seat against which the diaphragm closes the valve.

The valve body may be made from plastic, metal, wood or other materials, depending on the intended application.

In diaphragm valves, the fluid is insulated from the mobile mechanism.

This makes diaphragm valves ideal for corrosive services, dangerous, etc., as they prevent contamination to and from the outside.

The diaphragm valve is a linear motion valve that is used to start, regulate, and stop fluid flow.

They valves can open quickly.

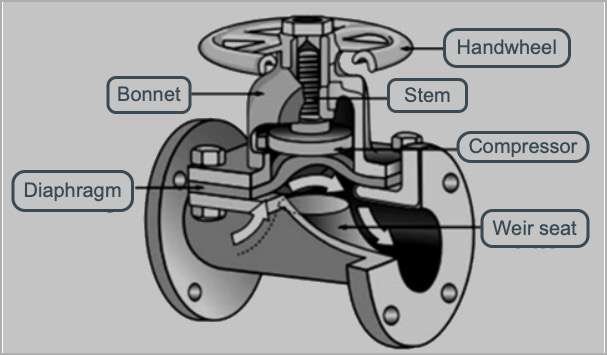

The figure below shows a diaphragm valve.

How do membrane valves work?

Diaphragm valves are very simple in construction and operation.

The valve actuator is attached to the internal membrane (or “diaphragm”) of the valve in its open position.

When the operator wants the valve to close, he presses and/or rotates the actuator and the actuator pushes the diaphragm towards the seat, thus closing the valve.

Certain diaphragm valves also work with the diaphragm in intermediate positions regulating the flow of fluid through the valve.

Valve actuation

A compressor is required to operate the diaphragm in the valve. The compressor is a disc that lies between the valve stem and the diaphragm.

The compressor is linked to the diaphragm and distributes the forces from the stem during linear movement.

When the compressor operates from its open position, it pushes the diaphragm up to the seat to ensure closure.

Manual membrane valves are ideal for flow control with precise variable opening.

The operator must turn the valve wheel until the desired amount of fluid circulates in the pipe.

For open or closed position applications, the handwheel is turned until the actuator pushes the diaphragm against the bottom of the valve body to stop flow or rises to open the flow

Types of Diaphragm Valves

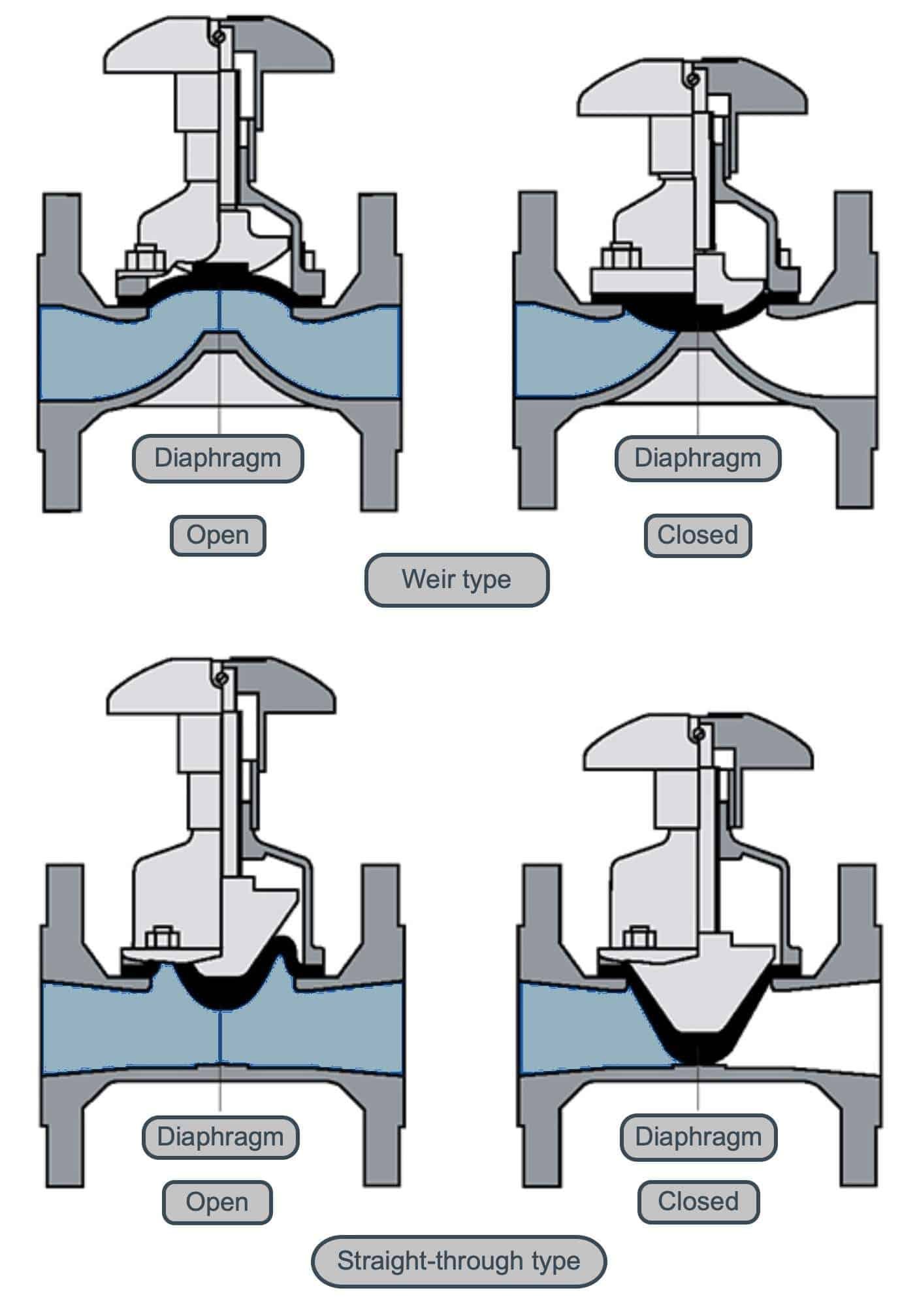

Diaphragm valves are available in two basic forms: weir or direct type.

The basic structure of the two valves is similar, except for the body and diaphragm.

Weir Type

The weir type design is the most popular type of diaphragm valve and it is preferred for general applications.

They are better utilized for controlling small flows.

The weir-type body has an elevated lip to which the diaphragm comes in contact.

Weir type valves use a smaller diaphragm because the material does not need to stretch so far. The material can be strongest such that the valve can be used for high pressure and vacuum services.

How does the Weir Type Diaphragm Valve Work?

Weir type diaphragm valve has a flexible diaphragm that is connected to the compressor.

The compressor is connected to the stem. To increase the flow rate the stem moves upwards.

While the stem moves upwards, it moves together with the compressor since they are connected.

The compressor in turn is linked to the diaphragm and this causes the diaphragm to move up as well.

When the diaphragm moves upwards, the flow of the fluid increases. To reduce the flow rate or to completely close the flow, the stem is turned and moved downwards.

The stem, then transfers the downward motion on the compressor which also presses the diaphragm downwards to either reduce the flow rate or to completely close the fluid flow.

Weir-type bodies have bonnet assemblies recommended for handling dangerous fluids because if the diaphragm fails the hazardous materials will not be released into the surrounding system.

The Straight Through Type

The body of this design has a flat bottom that is parallel to the flow stream.

This allows the flow to move through the valve with no major obstructions.

A flexible material is required for the diaphragm so that the mechanism can reach the bottom of the valve body; this can shorten the life span of the diaphragm.

Specifically suited to handle erosive and abrasive applications, its unobstructed full bore provides excellent performance with low pressure drop.

At valve fully open offers self cleaning design. It is the best choice for dirty, contaminated and powder media.

Slurries are efficiently handled by the Straight Through Valve design.

They are not well suited for high temperature fluids.

The major benefit of a membrane valve is that the membrane isolates the moving parts of the valve from the process fluid.

This makes them suitable for handling aggressive fluids and suspended solids.

In addition, as the bonnet assembly is not exposed to the fluid, it can be made from inexpensive materials such as cast iron, thereby reducing the overall cost.

Developing new diaphragm materials makes it possible to use diaphragms on most fluids.

However, their application is limited by the temperature that the diaphragm can support – generally less than 175°C.

Diaphragm valves are generally used in process fluid applications.

In a diaphragm valve the body and diaphragm are the only wetted pieces of the valve, allowing for chemically compatible materials to be selected for almost any process media.

Applications – Diaphragm Valve

Membrane valves are ideal for:

- Corrosive applications, in which body and diaphragm materials may be selected for chemical compatibility (For example, in water demineralization plants where they operate with acid and alkaline fluids, etc.)

- Abrasive applications, where body coating can be designed to resist abrasion and diaphragm can be easily replaced when worn out.

- Solids entrained liquids, since the diaphragm can seal around any entrained solids and provide a positive seal

- Slurries, because the diaphragm can seal around the driven solids and provide a positive seal.

Services

Membrane valves are widely used in the following markets:

Water and waste water.

Power

Pulp and Paper

Chemical

Cement

Mining & Minerals.

Pharmaceuticals and bio-processes.

In the figures below we show different types of diaphragm valves

Read our next article in which Plug Valves are detailed.

Diaphragm Valve – Calculate Man Hours