Pressure-relief devices are used to remove overpressure, which could result in the failure of a boiler, pressure vessel or other equipments. A pressure relief device is the last line of defense for safety.

Pressure-relief devices are used to remove overpressure, which could result in the failure of a boiler, pressure vessel or other equipments. A pressure relief device is the last line of defense for safety.

If all other safety devices or operational controls fail, the pressure relief device must be able to evacuate the overpressure.

They can be used to release gas, steam, liquids or vapors.

There are many kinds of pressure relief devices available to the boiler and pressure vessel industry.

The most common types of pressure relief devices are:

Safety Valve

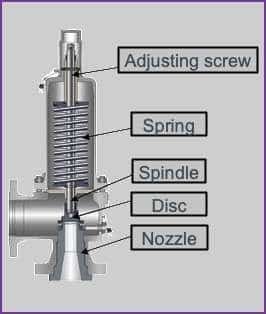

This device is typically used for steam or vapor service. It operates automatically with a full-opening pop action and re-closes when the pressure drops to a value consistent with the blowdown requirements prescribed by the applicable governing code or standard.

Safety valves are used for compressible fluids (gas and vapors) and characterized by the rapid action of opening and closing.

Safety valves are widely used in steam plants for boiler overpressure protection. They are classified into three groups based on the amount of travel or lift during the pop-up.

Low-lift safety valves have a small capacity and the valve lifts 1/24th of the bore diameter.

High-lift safety valves travel 1/12th of the bore diameter.

Whereas Full-lift safety valves travel at least 1/4th of the bore diameter and best suited for steam services.

It is important to ensure that the safety valve is capable to operate at all times and under all circumstances.

A safety valve is no process valve or pressure regulator and should not be misused as such. It should have to operate for one purpose only: overpressure protection.

Relief Valve

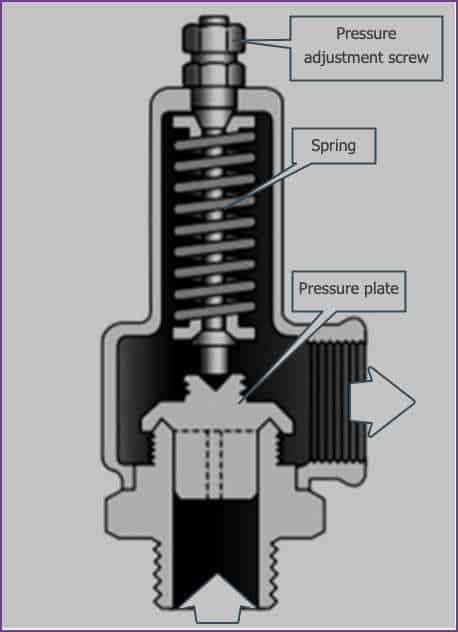

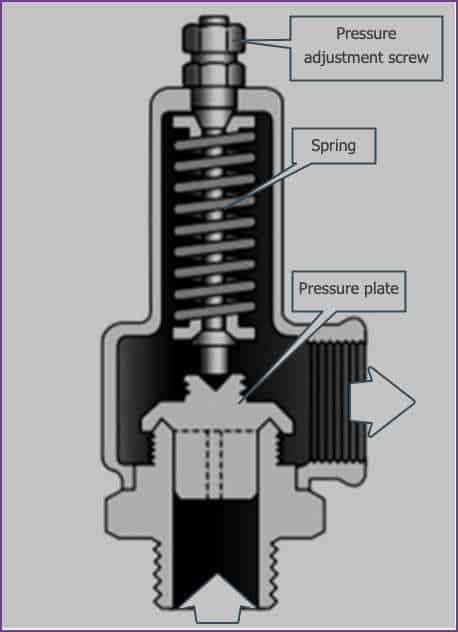

The relief valves are spring loaded, with gradual opening and closure.

They are driven by upstream pressure and appropriate for incompressible fluids. Adjustable relief valves allow the pressure setting adjustment through the outlet port.

For a spring-loaded relief valve, the force of the spring keeps the disc in the closed position of the valve.

When the line pressure exceeds the defined pressure, the disc begins to lift, allowing the fluid to circulate through the outlet and release the pressure.

With a further increase in input pressure, the disk lifts further. When the disc is at its nominal value, the valve is fully open and the system pressure is released.

Once the overpressure within the system falls under the force of the spring, the spring pushes the disc positively to close the valve, preventing fluid release.

Electronic safety valves provide zero leaks with electrical controls to monitor and regulate system pressure.

Safety Relief Valve

This device includes the operating characteristics of both a safety valve and a relief valve and may be used in either application.

Temperature and Pressure Safety Relief Valve

This device is typically used on potable water heaters.

In addition to its pressure-relief function, it also includes a temperature-sensing element which causes the device to open at a predetermined temperature regardless of pressure.

The setpoint temperature for these devices is normally 210°F.

Vacuum Relief Valve

A vacuum relief valve is designed to prevent excessive internal vacuum by admitting fluid. Once the normal condition is restored, they close again and prevent further fluid flow.

Pilot Operated Safety Valves

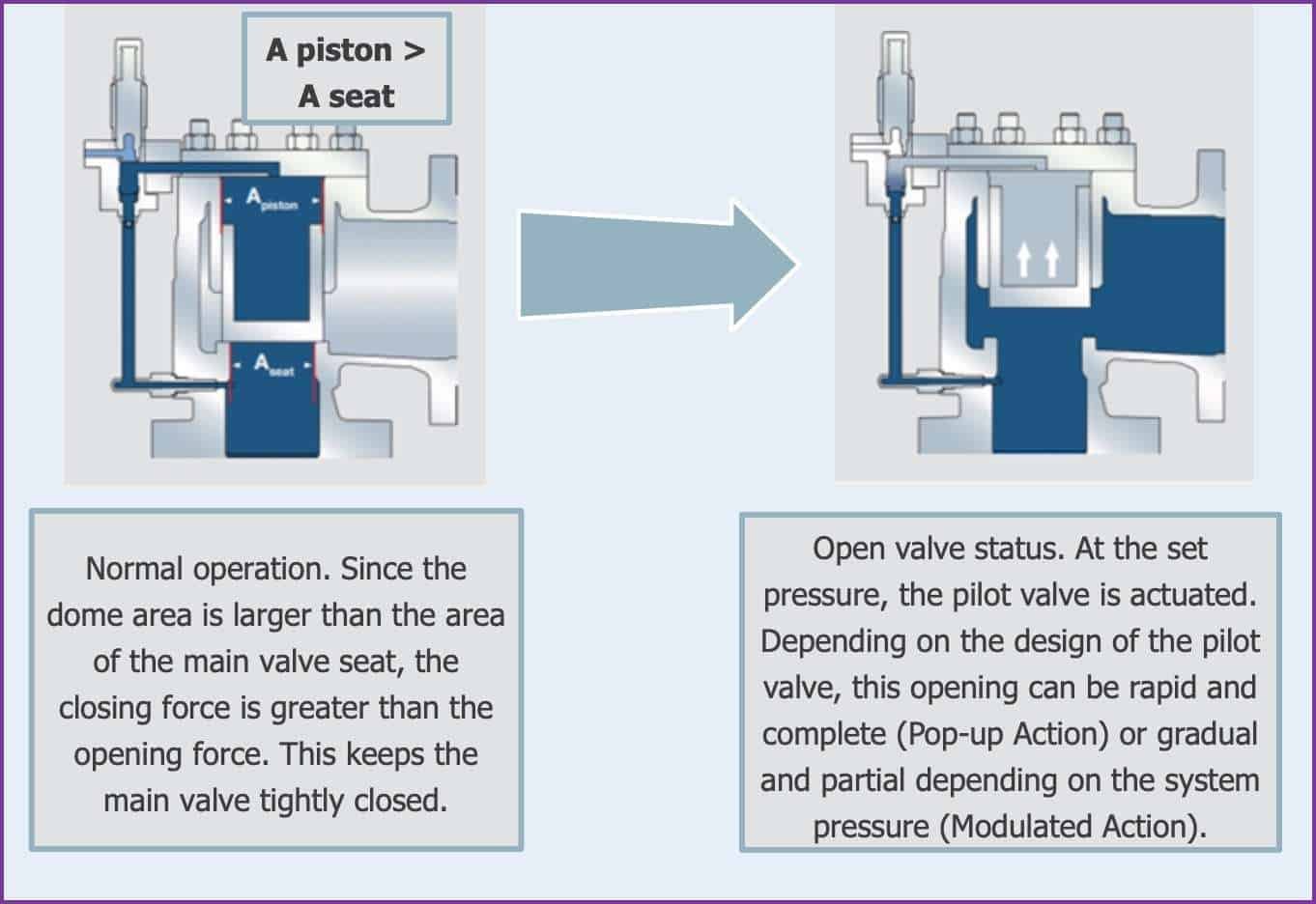

Pilot operated safety valves (POSV = “pilot operated safety valves”) are controlled by the process medium in which they operate.

This is done by transferring the system pressure to the pilot valve via the pressure line.

The pilot valve uses the dome space on top of the main valve piston to open and close the main valve.

In systems that operate with fluids such as flammable gases, the fluid released from the valve is typically directed to a high-gas stack, where it is burned and the resulting flue gases are emitted to the atmosphere.

That applies, for instance, to petroleum refineries.

In non-hazardous systems, fluid is often released into the atmosphere via a suitable discharge pipe designed to prevent clogging by rain, ice, dust, etc. As a result, the adjusted head pressure is unaffected.

It should also be noted that the discharge pipe must be placed so that it does not pose a hazard to personnel.

A pressure relief valve shall be operable at all times, especially in the event of a power failure.

Therefore, the only reliable power source for a pressure relief valve is the process fluid.

Location of Pressure Relief Valves & PSV

Process engineers decide on the location of pressure relief valves. They mention PRV & PSV requirements in the P&ID.

Benefits of Pressure Relief Valves & PSVs

The main advantage of installing a pressure relief valve in a system is that they vent the fluid to protect the system from overpressure, and close and prevent loss of this fluid once system pressure is acceptable again.

Installing safety valves protects system components from damage and reduces the impact on the environment.

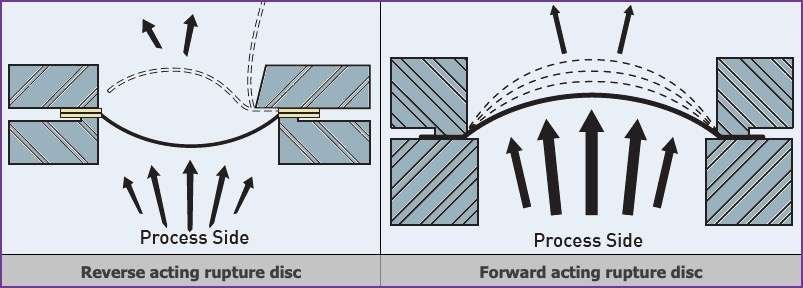

Rupture Disk

This device is classified as non re-closing since the disk is destroyed upon actuation.

This type of device may be found in use with a pressure vessel where a spring-loaded pressure relief device is inappropriate due to the operating conditions or environment.

Pressure relief devices must operate as designed in order to perform their required task.

Pressure Relief Device Examples – Calculate Man Hours