Prefabricated pipe manufacturing times. The prefabrication of the pipe spool ensures the reduction of piping assembly costs and high quality in manufacturing products.

Prefabricated pipe manufacturing times. The prefabrication of the pipe spool ensures the reduction of piping assembly costs and high quality in manufacturing products.

Time per Prefabricated Pipe

In piping work, it is crucial to carry out good engineering that allows us to work with prefabricated piping in the shop or on field.

The subject we develop in this post applies to cases of piping where quality control is carried out by hydraulic tests.

Once the spools or prefabricated are finished, they are transferred to the construction site in order to assemble them according to the drawings.

In general, with standard engineering, the number of welds to be performed during prefabrication is between 70% and 90% of the total to be performed.

In our example, we estimate that all the welds on the fittings are done in an on-site workshop.

Assumption:

We assume that the welding time in the workshop is half the time needed on-site.

The pump assembly is within 3mm.

Mounting adjustments are made to the nipples in two dimensions.

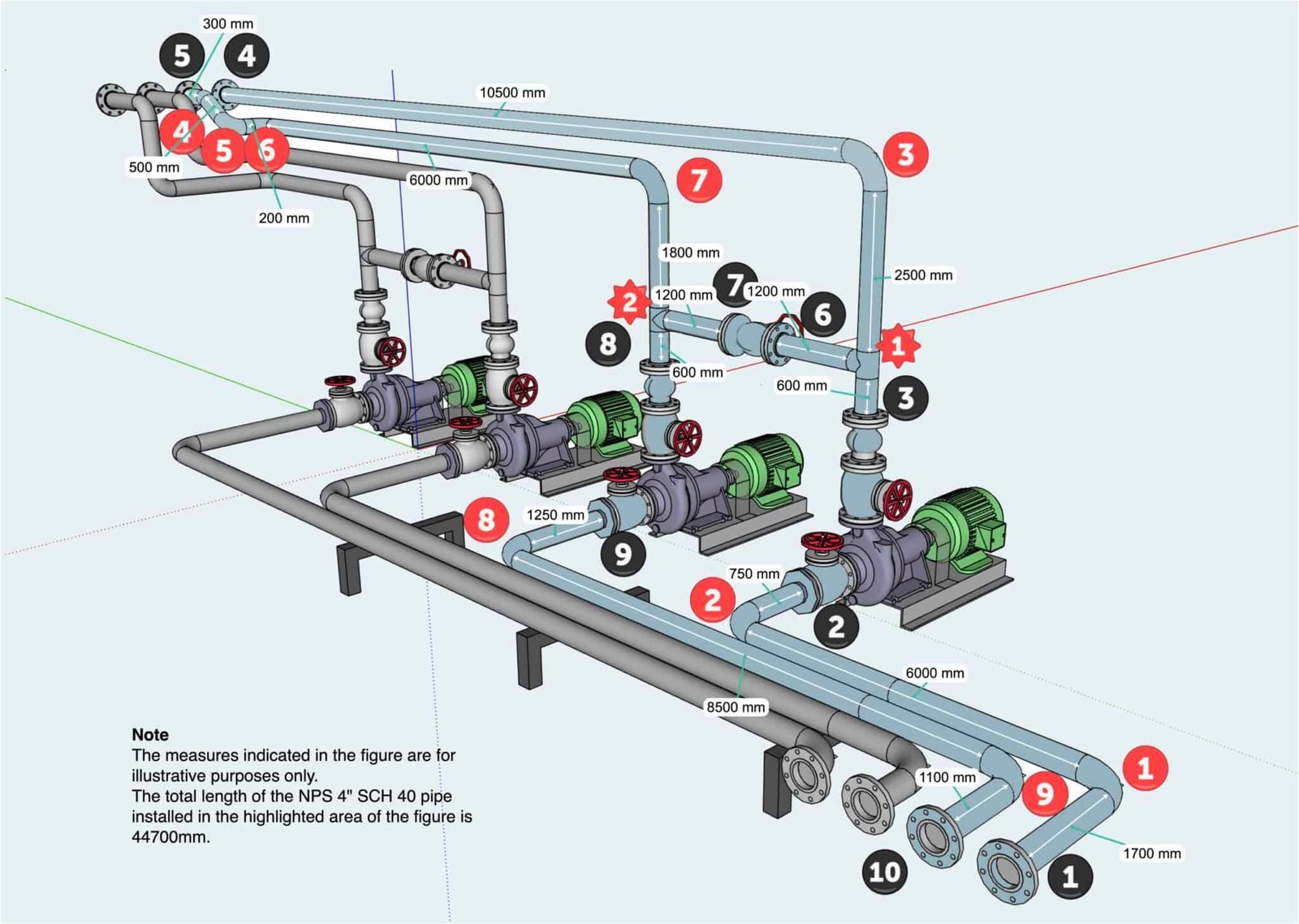

Piping illustration

Using the data in the illustration of the piping and what is stated in the assumption, we will calculate the total number of person-hours for our example.

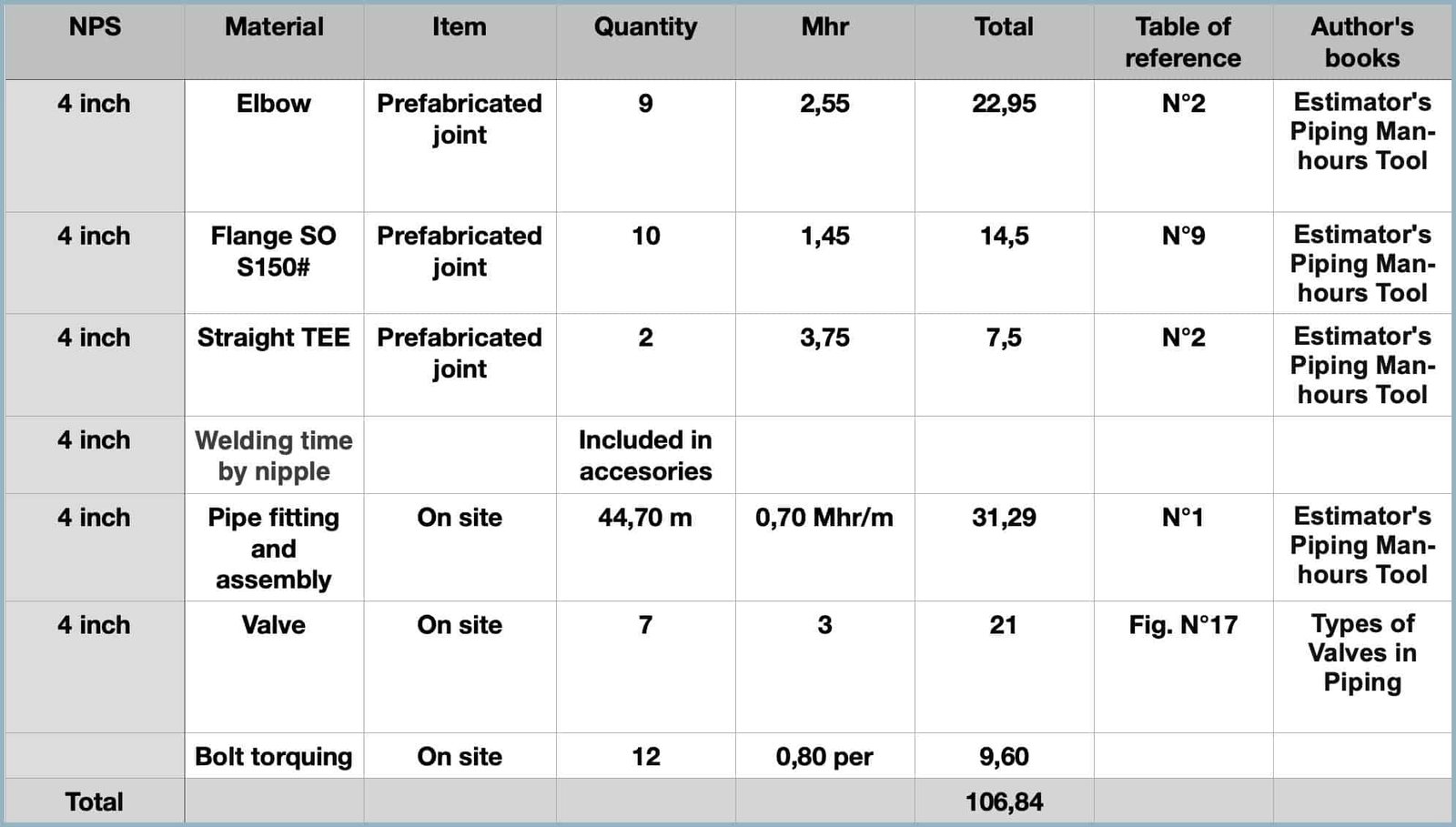

Table of time per prefabricated pipe

Time per Prefabricated Pipe

In the previous post, we had estimated 151.79 hours for assembling in the field.

In other words, with prefabrication, we save 44.95 person-hours, or around 30% of the assembly time.

The advantages of working with prefabrication

The way to reduce the consumption of hours and to assure quality is using the prefabricated pipes, this also guarantees the fulfillment of the Plans of Work.

As a rule of thumb, we can say that:

“Everything that is manufactured in the workshop is more economical and of higher quality than what is done on-site”.

The success of industrial construction projects depends largely on the quantity and quality of the prefabricated. When prefabricated, the piping work is divided into two stages: prefabrication of Spools in Workshop and transport and installation with on-site adjustment.

Timely delivery of piping spools to the installation site is the key to the success of the entire Project!

Prefabricated pipe manufacturing times – Calculate Man Hours