Heavy equipment cost. Learn how to calculate heavy equipment cost per hour with this complete guide. Cost heavy equipment per hour with this complete guide. Calculate the cost per hour of your heavy equipment using formulas.

Heavy equipment cost. Learn how to calculate heavy equipment cost per hour with this complete guide. Cost heavy equipment per hour with this complete guide. Calculate the cost per hour of your heavy equipment using formulas.

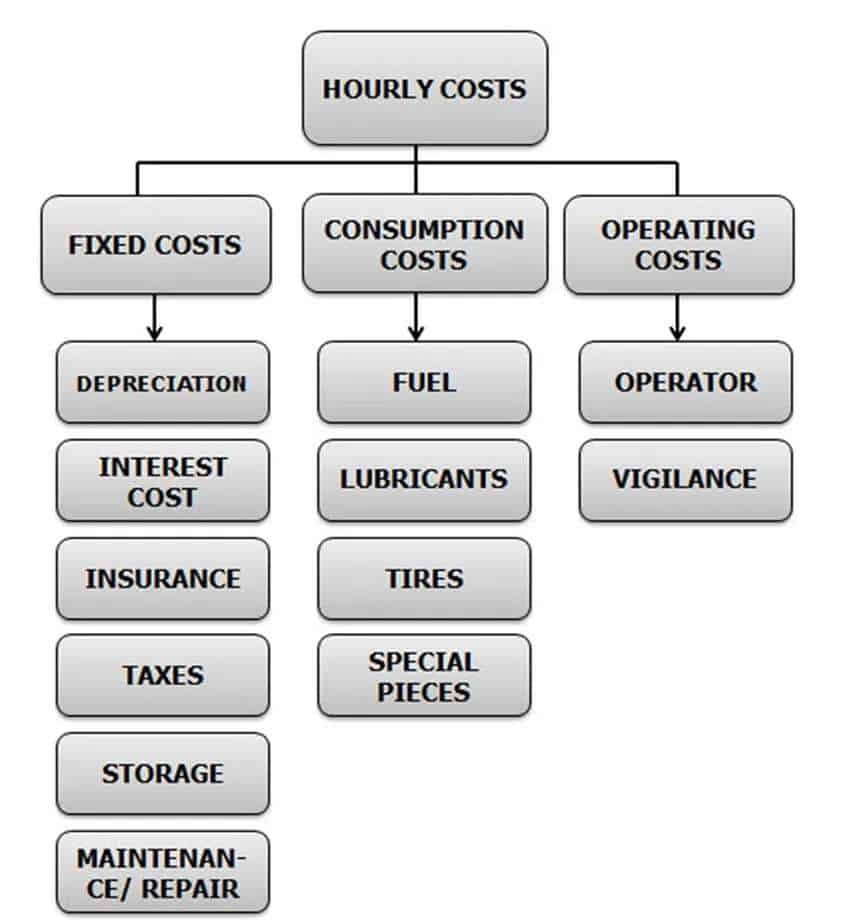

The following diagram lists the items that make up the cost per hour of the equipment.

How to Calculate Heavy equipment rental per Hour.

Summary chart

Applying the above table, we have:

Heavy equipment cost – Fixed Costs per Hour

Depreciation

Depreciation charge:

D= [Vn-Vrev/Vu]

Average interest on investment = Im at the annual interest rate = i

The charge to be added to the cost of the equipment for the average interest of the investment is equal to:

The average value of the equipment by the annual interest, divided in 2000 hours per year.

Im = { [Vn + Vrev]/2 * 2000}*i

Cost of insurance, taxes, and storage

The costs for insurance, taxes, and annual storage fees are:

Insurance cost: 5.5% of the average value of the equipment.

Cost for taxes: 1.5% of the average value of the equipment.

Cost of storage: 1.5% to 2% of average equipment value.

We get hourly costs by dividing the amounts by the number of annual work hours: 2000 hours.

Maintenance and repairs of machinery

Maintenance for repair and spares costs.

The cost per hour of maintenance for repair and spares is equal to:

Cost of maintenance for heavy work: 80 to 100% of the depreciation value.

Cost of maintenance for normal work: 70 to 90% of the depreciation value.

Cost of maintenance for light work: 50 to 80% of depreciation value.

Consumption costs

Fuels

Usually, each company records the fuel consumption, for example, during one month and then divides that data into the monthly working time of the machinery, thus getting the hourly fuel consumption.

The hourly cost for fuel consumption is the product of the expense for the price of fuel.

Lubricants

The correct method for finding out the hourly consumption of oil in a machine is to record the engine, hydraulic, and transmission oil consumption for changes and refills at the end of each month and then divide each data into the monthly working time of the machinery.

The cost to be taken for oil consumption is obtained by multiplying the hourly consumption of oils by their price.

Cost per consumption of machine or equipment tires because of their use

We get the hourly cost by dividing the price of the tire over the economic life of the tire.

A 15% bonus is also charged with the depreciation of the tire for tire repair.

Heavy equipment cost – Operating Costs

Labor costs – Calculate Man Hours

The cost of the worker’s hourly wage, plus social security contributions multiplied by the percentage affected, is equal to the hourly cost of the worker.

Labor cost for surveillance

The hourly cost for surveillance is equal to:

10% of the cost of labor.

Total Cost

Adding the above charges, we arrive at the estimate of the hourly cost of the equipment.

Knowing the amount of direct and indirect personnel to be employed in the work and the trips to be made, we can estimate the number of vehicles to be used and their fuel and maintenance costs, etc.

In this phase, the quantities and costs of the manual tools to be used (one toolbox per officer is calculated), the machinery and special equipment, for example, welding machines, generators, optical levels, theodolites, amperometric , etc., should also be evaluated.

The equipment necessary for the daily transport of materials and machinery to the site must also be computed.

Read the next article on How to Estimate Input and Consumption Materials

How to Calculate Equipment Cost per Hour – Calculate Man Hours