How to Estimate Input and Consumption Materials.

How to Estimate Input and Consumption Materials.

In this step, the estimator must determine the cost and quantity of input materials and consumables.

The term consumables refers to all ancillary material that is used to execute the work.

It is pointed out that this material is not incorporated into the construction.

On the other hand, the contribution or input material is also an auxiliary material, but it is incorporated into the construction.

This step of the estimation includes all indirect materials used during the execution of work.

Consumption Materials

Consumable materials are auxiliary materials used during the construction and assembly process of a project.

But as their name suggests, they are consumed and not detected in the finished project.

Examples of consumable materials:

Consumption materials in civil works

Some civil works estimators add the following costs to the consumable item, for instance;

- Waste of framework material, produced by cutting, reusing, and handling.

- The use of elements for the assembly and fastening of the form works such as nails, threaded rods, spacers, staples, etc.

Caution:

The framework has a significant value within the cost of m3 of concrete.

Consequently, their acquisition and assembly cost is charged as a direct cost.

Perishable tools

- For example, drills, cutters, saw blades, steel reamers, cutoff and roughing discs, etc.

Consumer materials in electromechanical works

For example, we list:

- Oxidizing gases, such as acetylene and oxygen, used in oxy-cut.

- Shielding gases, such as carbon dioxide, used in the process of short-circuiting and globular transfer welding.

- A traditional binary mixture of argon and carbon dioxide, used in the MIG/MAG process, and gas-shielded tubular electrode welding.

- Special gas mixes. To be used as a protective atmosphere in MIG, TIG, and plasma cutting welds.

- Carbon dioxide and nitrogen dioxide we use as protective or insulating inert atmosphere, etc.

How to Estimate Input and Consumption Materials – Input Materials

Input materials include any indirect material that is incorporated in whole or in part into the finished project.

Examples of input materials.

Input materials in civil works

For instance, we mention the following:

- The wire to bind the armor.

- Additionally, the spacers between the formwork wall and the reinforcement iron.

- Building additives, etc.

Input materials in electromechanical works

For example, we can mention the following:

- Electrical connectors and terminals, insulating tape, minor screws, adhesives, etc.

- Soldering and brazing filler metals.

- Also, filler materials for electric arc welding.

Attention:

When working with a significant amount of inches of solder or with alloyed or special steels, the cost of these materials is undoubtedly considerable.

Cost of input materials and consumables

- Usually, the cost of these materials is estimated as a percentage associated with the volume of what is being built.

- However, this is not valid for materials of higher unit cost, such as electrodes, which are calculated by their cost and quantity.

Charts

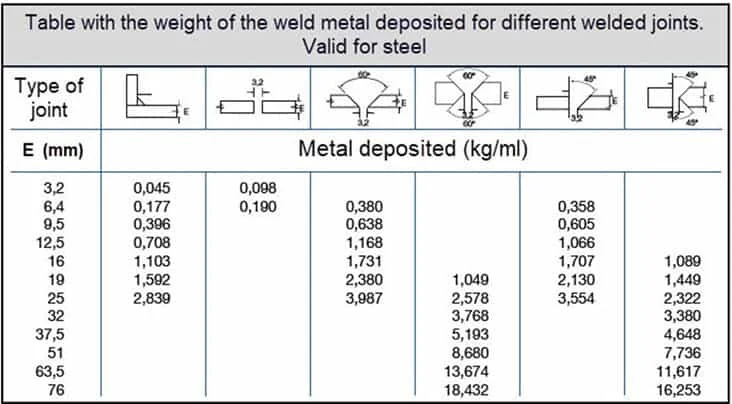

Deposited metal weight vs. joint type table

In this case, the table shows the weight of metal deposited in different joints per linear meter.

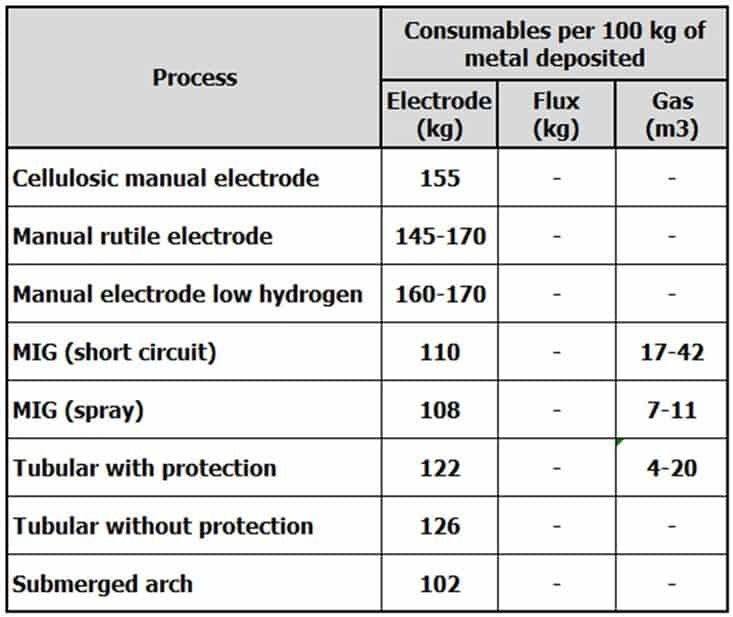

Welding process vs. consumables

Table to calculate the amount of inputs needed in each welding process to deposit 100 kg of metal.

See next post on how to calculate indirect labor hours.

How to Estimate Input and Consumption Materials – Calculate Man Hours