Steps to identify direct materials, inventory them, and inquire about their costs, delivery times, and payment conditions. The term “materials” includes:

Types of materials

- Semi-finished materials, such as metal profiles, are used in the construction of structures.

- Cataloged materials.

- Processed materials, such as equipment, are assembled with other pre-manufactured components.

Here, the estimator must identify each of the materials, compute their quantities, inquire about their prices, delivery times, and payment conditions.

We must complete the task above within a limited timeframe to ensure that the information is available at the right time for inclusion in the offer.

We define the specifications of the required materials in the bidding documents. In case of any doubts, bidders can make inquiries and request clarifications from the acquirer up to a certain number of business days before the submission of the proposals.

The contractor’s written responses to the queries and requests for clarification are, as mentioned above, equally notified to all bidders and become part of the bidding documents.

How to Calculate Direct Materials Cost – Raw Materials Inventory

At this stage, it is necessary to emphasize the importance of conducting an accurate calculation of the required materials.

Beware, even a small error in the calculation of expensive materials can result in significant magnification of the error.

Cost of materials

Once the identification and counting of materials is completed, the commercial activities of obtaining estimates for each material, including delivery times and payment terms, begin.

Quotation form

A common and effective practice for elaborating on the quote is to divide the project into categories, subcategories, and items. Each item groups the materials and labor required to execute a specific task.

Examples of categories

Civil works category, piping and equipment category, electrical works’ category, instrumentation and control category, pre-commissioning, and commissioning category.

The specialists of each category will divide them into subcategories, and within each subcategory, there will be unique items and subtopics for estimating the Direct Material Cost.

A- Civil works category.

A-1-Subcategory: Reinforced concrete base.

-A-1-1 Item: Excavation and preparation of resistant soil.

-A-1-2 Item: Cutting, bending, and arming of the reinforcing iron.

-A-1-3 Item: Construction and assembly of form-work.

-A-1-5 Item: Casting of concrete.

-A-1-6 Item: Dismantling and cleaning form-work.

B- Category Piping and Equipment – Estimate the Direct Material Cost.

B-1 Subcategory: Aerial piping.

-B-1-1 Item: Identification of materials and construction of prefabricated.

-B-1-2 Item: Hydraulic testing of prefabricated products.

-B-1-3 Item: Painting and transfer of prefabricated elements.

-B-1-4 Item: Assembly of prefabricated, supports, and change sections.

-B-1-5 Item: Final hydraulic test and paint touch up.

C- Electrical Category.

C-1. Subcategory: Placement of buried ducts.

-C-1-1. Item: Excavations.

-C-1-2. Item: Assembly and fixing of conduits.

-C-1-3. Item: Lean concrete casting.

-C-1-4. Item: Assembly of cables and their identification according to technical specifications.

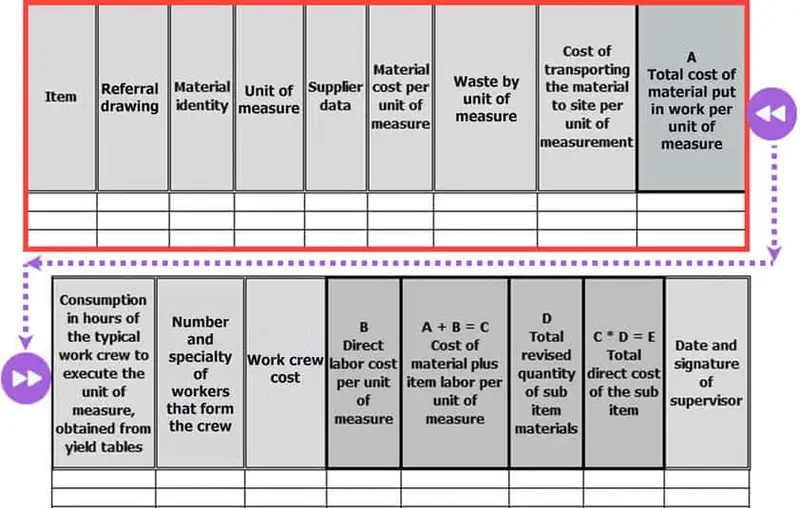

Once the project has been divided into categories, subcategories, and items, we must record the following in each item:

-We examine the drawing or documentation of the item.

-We compute the material under it specification.

-The unit of measurement used and the data from each supplier.

-The unit cost of each material that comes from the sum of:

-The unit cost of the material at the supplier’s premises.

-The percentage of waste per unit.

-The cost of transporting it to the site.

These spreadsheets also record the hours of consumption required for work crews to perform each activity per unit of measure.

Chart for Recording Inventory and Material Costs of Project

The following figure shows a typical template for recording and testing tasks.

In the figure, we highlight the inventory, and direct cost of materials in a red box.

Chart for recording inventory and material costs of project XXX.

PROJECT: XXX.

TEMPLATE: Material and labor cost per item.

CATEGORY: A | Civil works.

SUBCATEGORY: A-1 | Reinforced concrete base.

How to Estimate the Direct Material Cost (Examples) – Cost Control Tools and Techniques

The most used tool for this task is the Microsoft Excel program, since it allows the use of many formulas and pre-designed templates that save work.

The Excel spreadsheet format is built once, and then this template is used for other jobs, adapting it to each project.

Excel also allows you to quickly change any calculation or cost.

But if you want to save even more time and avoid human error in data capture, it is convenient to use software to automatically inventory the data., for example, from Auto CAD.

The advantage of using pre-integrated applications and tools is that each change updates all data without the need to re-enter all the information.

Review the next article on How to Calculate the Man Hours.

How to Calculate Direct Material Cost (Examples) – Calculate Man Hours.