Accurate estimation of man-hours of assembling piping

In this procedure, the estimate is executed analytically, that is, by grouping the work according to the type of task, and applying the proven historical performance of each task.

Historical performance

Using historical performance is by far the best way to estimate the time to complete each task.

To make this possible, the organization retains the actual amount of effort expended to complete each task in previous projects.

Historical performance records provide valuable information for accurate estimates of future work.

Historical times to complete a job include:

Productive time: Time actually spent by the worker in producing or executing a task.

Contribution time: Time spent by the worker performing the support tasks required to perform each productive activity (Preparation, displacement, measurement, cleaning, security, etc.).

Non-contributory time: Any activity that is not included in the preceding categories and that is catalogued as a loss (Time of use of toilets, rest, etc.).

Conditions under which the estimations are valid (See the preceding post)

Pipework diagram – piping estimate

The figure below illustrates the piping diagram.

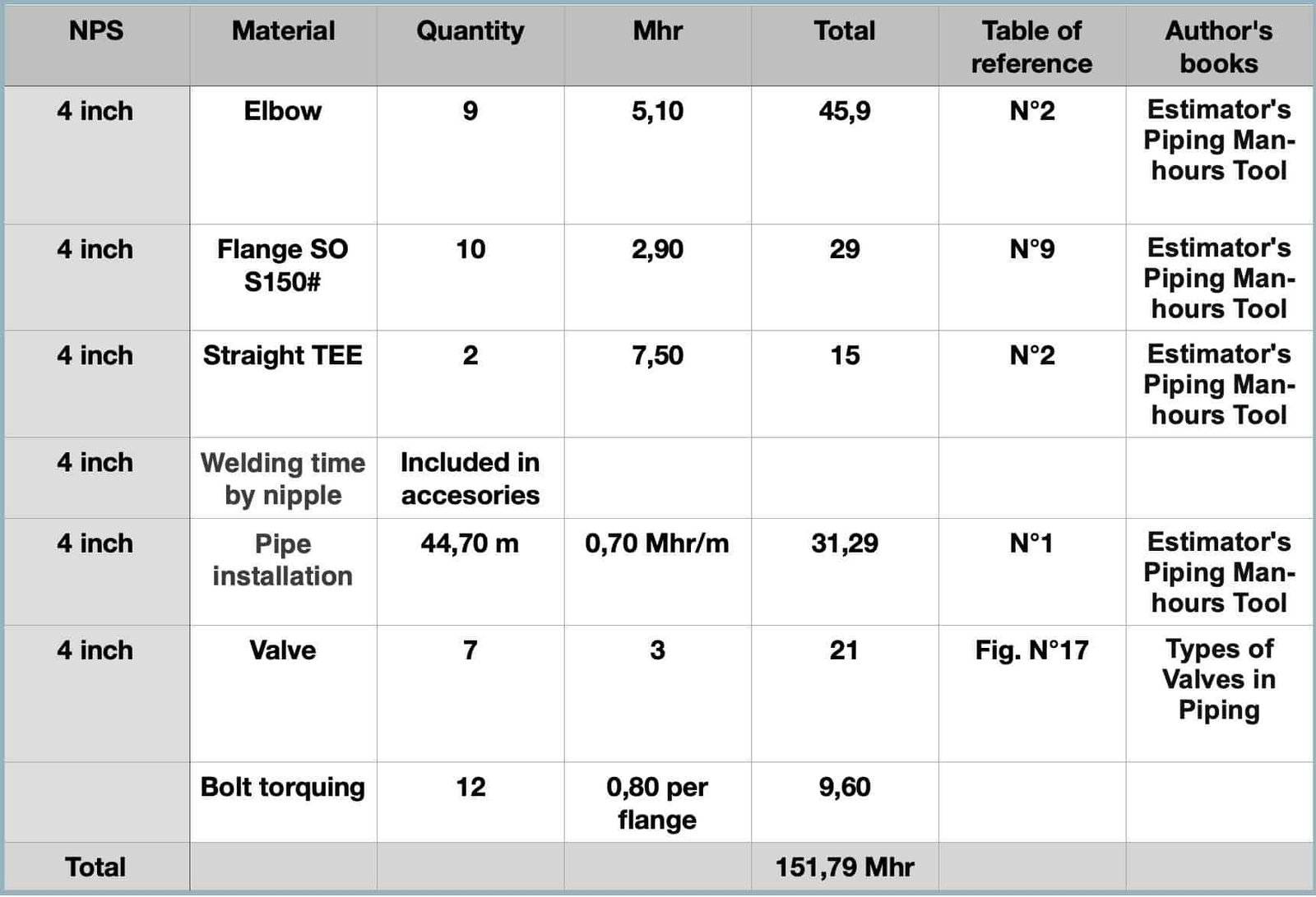

Chart with summary of hours of work

The following table summarizes the hours of work.

Historical assembly times are based on the books of the author.

Note that in the calculation, there are no hours charged for:

Fabrication and erection of supports

Pipework sandblasting and painting.

Pump assembly

Number of crew working days – piping estimate

Important:

151.79 man-hours corresponds to the working hours of a crew consisting of a welder, a pipefitter and an assistant working 8 hours per day for 6.32 days.

151.79/24 hr = 6.32 days.

In the next entry, we will calculate the time consumed during prefabrication.

Precise Piping Man-Hour Calculations – Calculate man-hours