Valves are mechanical devices that control the flow and pressure inside a system or process and are essential components of a piping system that carries liquids, gases, vapors, sludge, etc.

There are various types of valves available in the market; for example

Gate valve, globe valve, ball valve, butterfly valve, check valve, needle valve,

diaphragm valve, pressure relief valve, control valve, etc.

Each of these types has a model number that defines their unique characteristics and functions.

Valves are costly and it is essential to identify the type of valve to be used in each piping system.

General Information on the Valves – Types of Valves in Piping

We define a valve as a device by which the flow of a fluid can be started, cut or regulated by a moving piece that opens or blocks its way.

The valve variations available for use in pipework systems are vast.

This is due to the wide array of functions that valves perform, the diversity of fluids transported by piping systems, and the various environmental conditions in which valves perform those tasks.

Description of the valves:

Main parts of the valve.

Although there are important differences in valve design, the common parts can be identified in Figure N°1.

Types of Valves in Piping – The Body

The body is the main structure of the valve that contains or to which the rest of the valve is attached.

The body must be of sufficient mechanical strength and resistance to corrosion, erosion, fluid temperatures and external temperatures to meet operating conditions.

The material from which the valve body is manufactured is critical in this regard and common materials in use include carbon steel, low alloy steel, bronze, brass, stainless steel, and Monel metal.

The disc, the seat, and the orifice

The arrangement of the disk, seat and orifice allows controlling the flow of fluids through the valve.

Whatever the shape and arrangement, the disc is the moving part which directly controls the flow.

The stationary part on which the disc rests is called the seat, and the aperture is the maximum inner opening through which fluids can pass.

The stem

The stem is used to move the disc.

This is generally a bolted stem, although sometimes the fluid under pressure displaces the disc.

There are two basic types of stem.

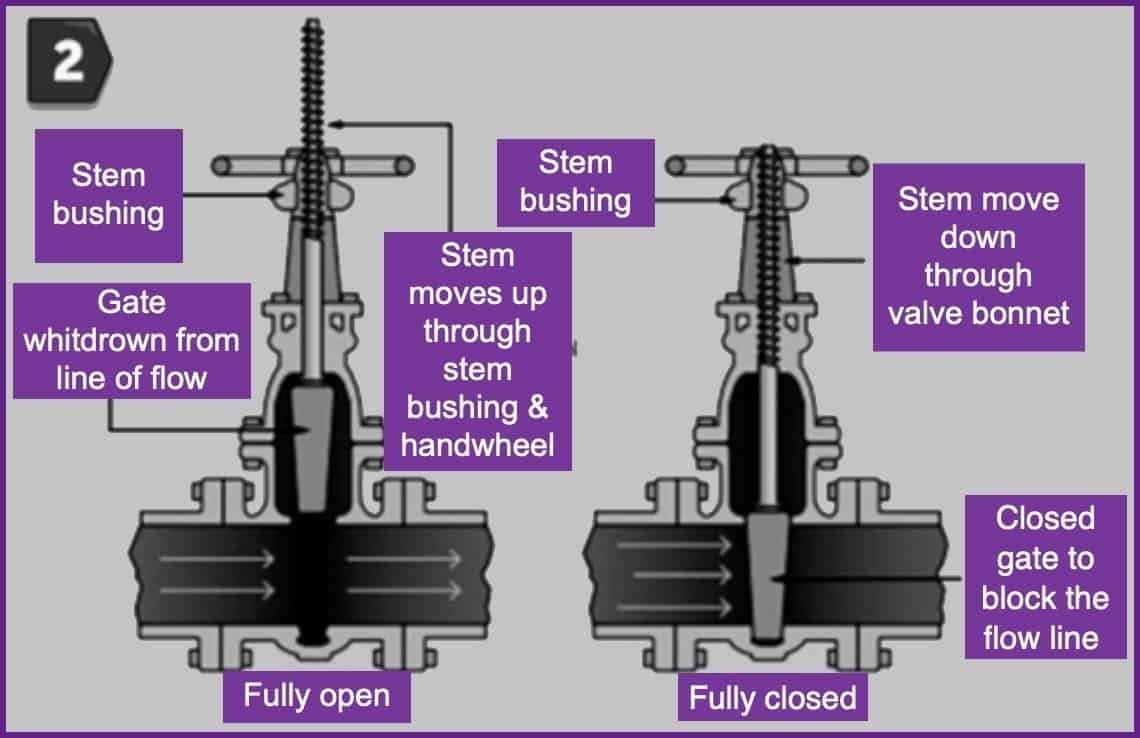

The ascending stem – Types of Valves in Piping

When the valve is actuated, the stem rises, lifting the disc with it.

The flywheel can go up with the stem, or the stem can go up through the flywheel.

These valves allow you to know at once the opening and closing position of a valve.

This is illustrated in Figure N°2.

The fixed stem

The stem stays in the same position, whether the valve is open or closed.

The disc lifts the thread from the stem when the valve wheel is operated.

The screw is located on the inside of the bonnet and in contact with the conveyer fluid.

The stem threads are exposed to the medium flow and are therefore subjected to its impact.

Consequently, this model is used when space is limited to allow linear motion of the stem, and when contact with the flow does not cause erosion, corrosion, or abrasion of the stem material.

See figure N°3

See also

In the next post, we’re going to talk about the gate valves.

Types of Valves in Piping – Calculate Man Hours