How to Calculate Equipment Cost per Hour.

How to Calculate Equipment Cost per Hour.

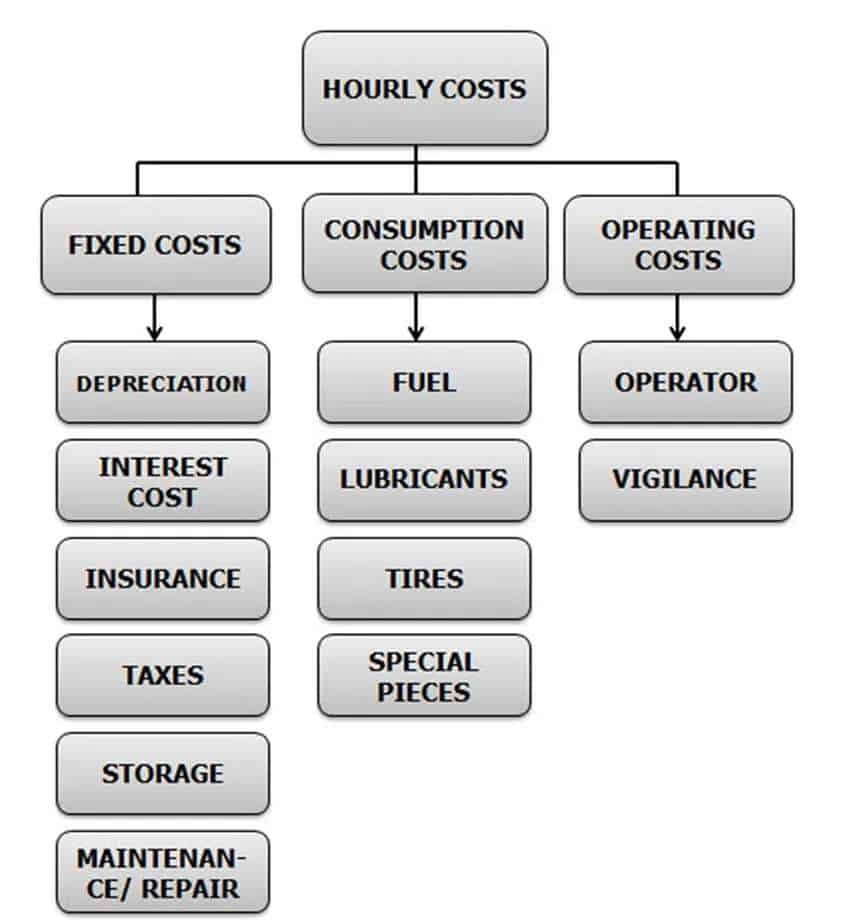

The following diagram lists the items that make up the cost per hour of the equipment.

Restricted content. You need to buy a membership to access it.

How to Calculate Equipment Cost per Hour.

How to Calculate Equipment Cost per Hour.

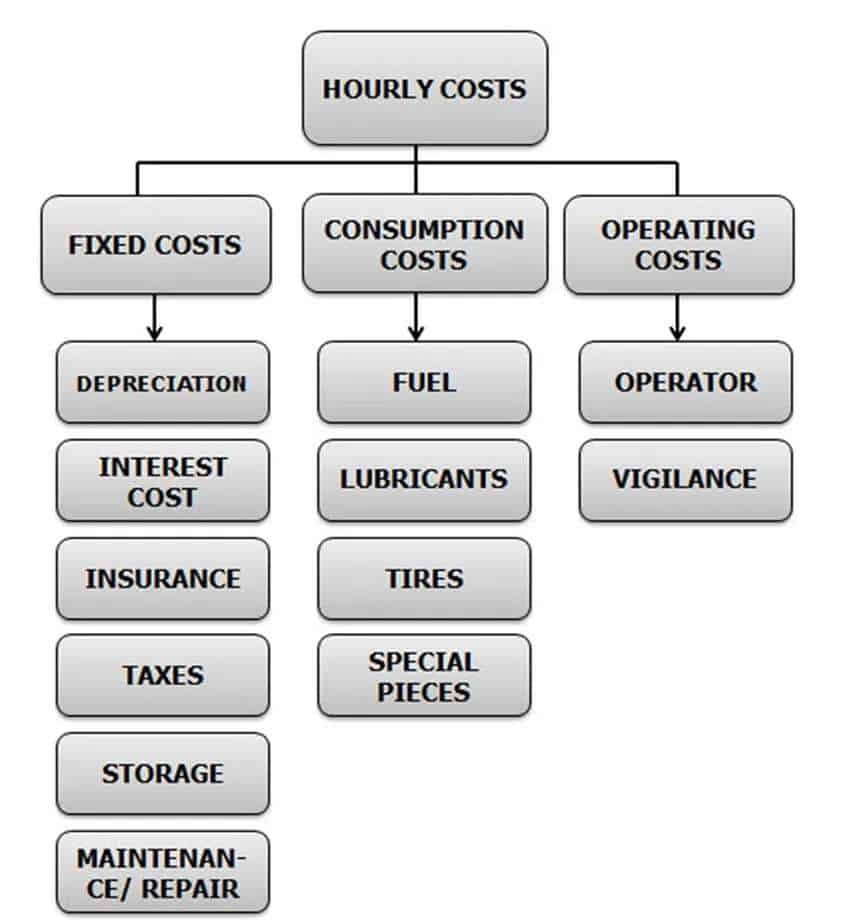

The following diagram lists the items that make up the cost per hour of the equipment.

Restricted content. You need to buy a membership to access it.